Plastics

Turning plastic waste into new useful things

REMADE in

the Inner West

Inner West Council,

2024 Environment Grant

Environment grants support projects that contribute

to an ecologically sustainable Inner West.

Project Objectives

Material Recovery

Provide reuse, repair, upcycling and/or recycling to enable materials to be continually used in a circular economy and move away from the linear concept of ‘produce > use > dispose’.

Community Engagement

Create support for community sharing of knowledge, skills and opportunities for a circular economy.

Waste Innovation

Support local new initiatives in the circular economy community to enable innovation in using materials otherwise seen as waste.

Sustainability Awareness

Increase awareness, improve access, inclusion, diversity and participation in circular economy initiatives.

Circular Services

Develop circular economy pathways or services within the Inner West.

The BIG Picture

A Community Sustainability Design Hub

Our ultimate goal is to create an accessible community focused sustainability hub which allows for new designs to be remade from plastic waste.

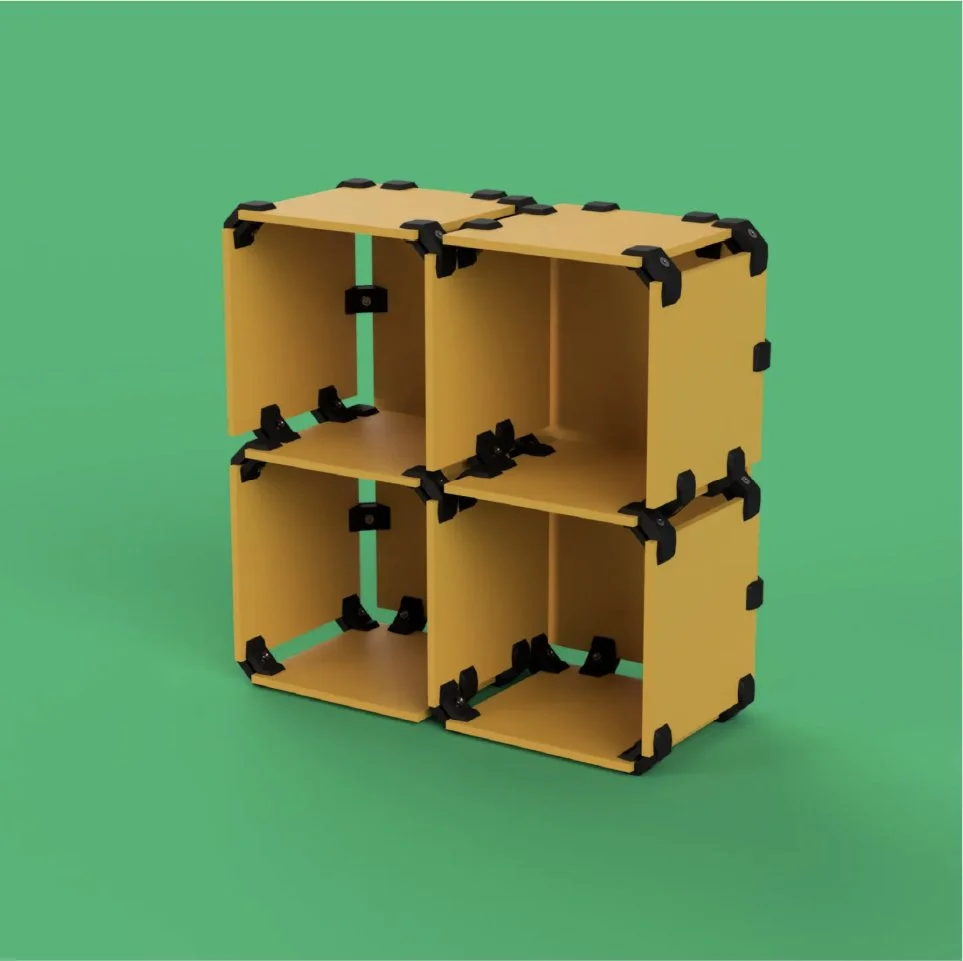

The design ethos of the community sustainability design hub is follow circular design principles to create only long-life, functional, and highly recyclable things.

Clips, toys, hooks

& more

A few things we are currently making from recycled plastics. These designs are made from 100% recycled plastic – recovered from the local area community.

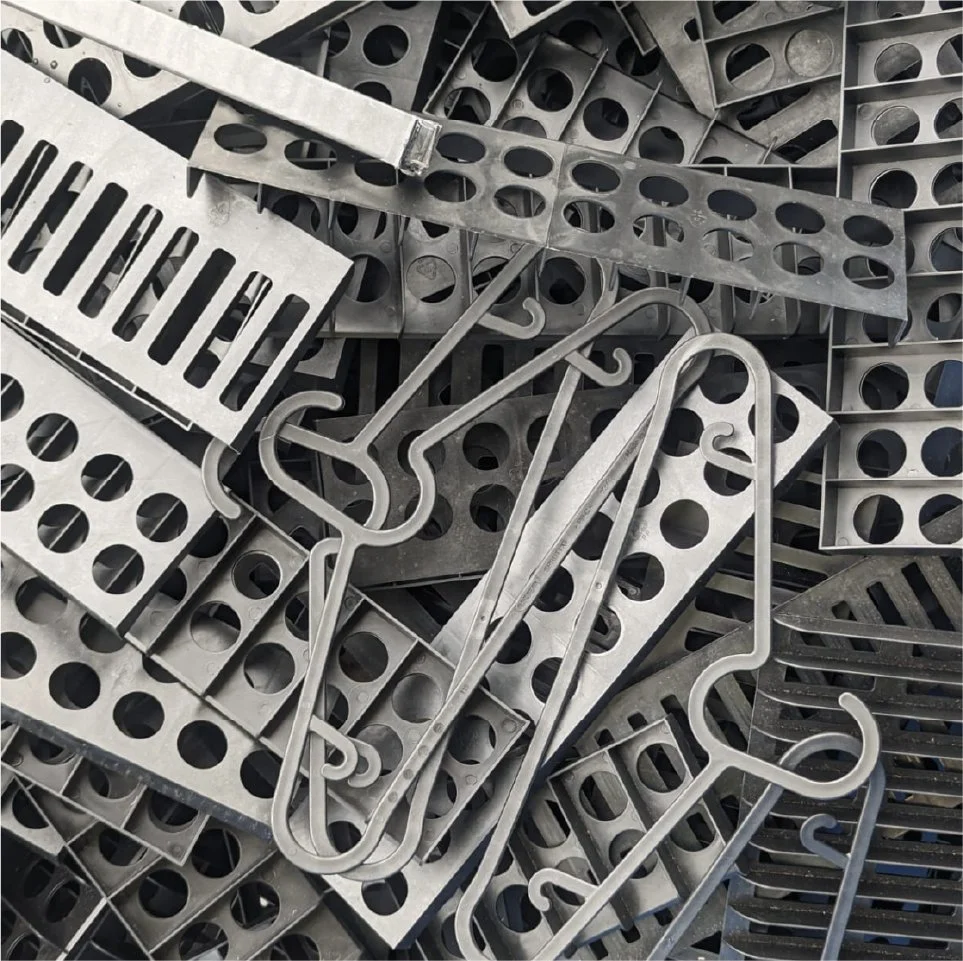

Carabiner(clip)

– CURRENT PROJECT

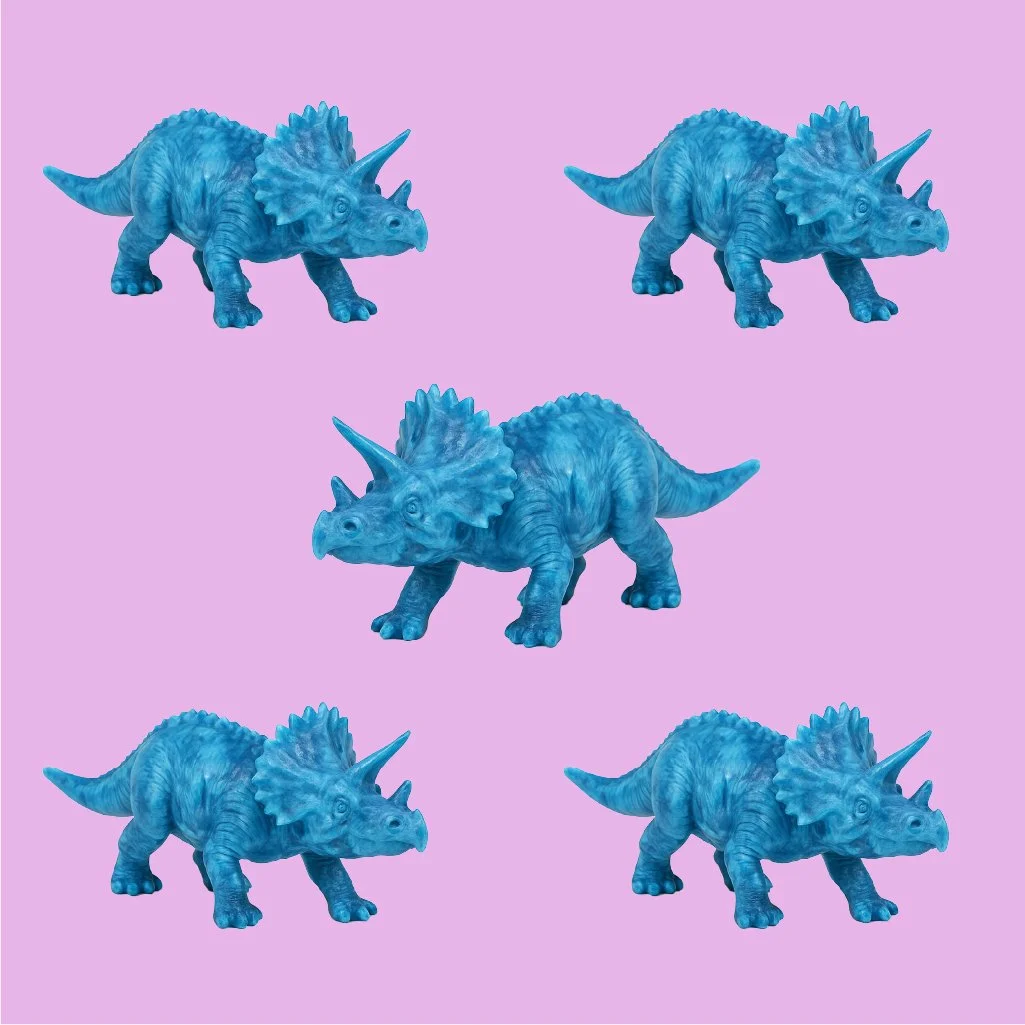

Dino toy

– IN-PROGRESS PROJECT

Hanging hooks

– PLANNED PROJECT

Bike accessories

– PROTOTYPE PROJECT

Bee cups

– PLANNED PROJECT

Modular furniture clips

– PLANNED PROJECT

Community sourced ideas

– OPEN TO SUGGESTIONS

The story so far…

How it works

1. Identifying Local Waste Sources

With a hyper local approach, the project identifies recyclable sources of plastic waste generated in the local area and collects them ready for processing.

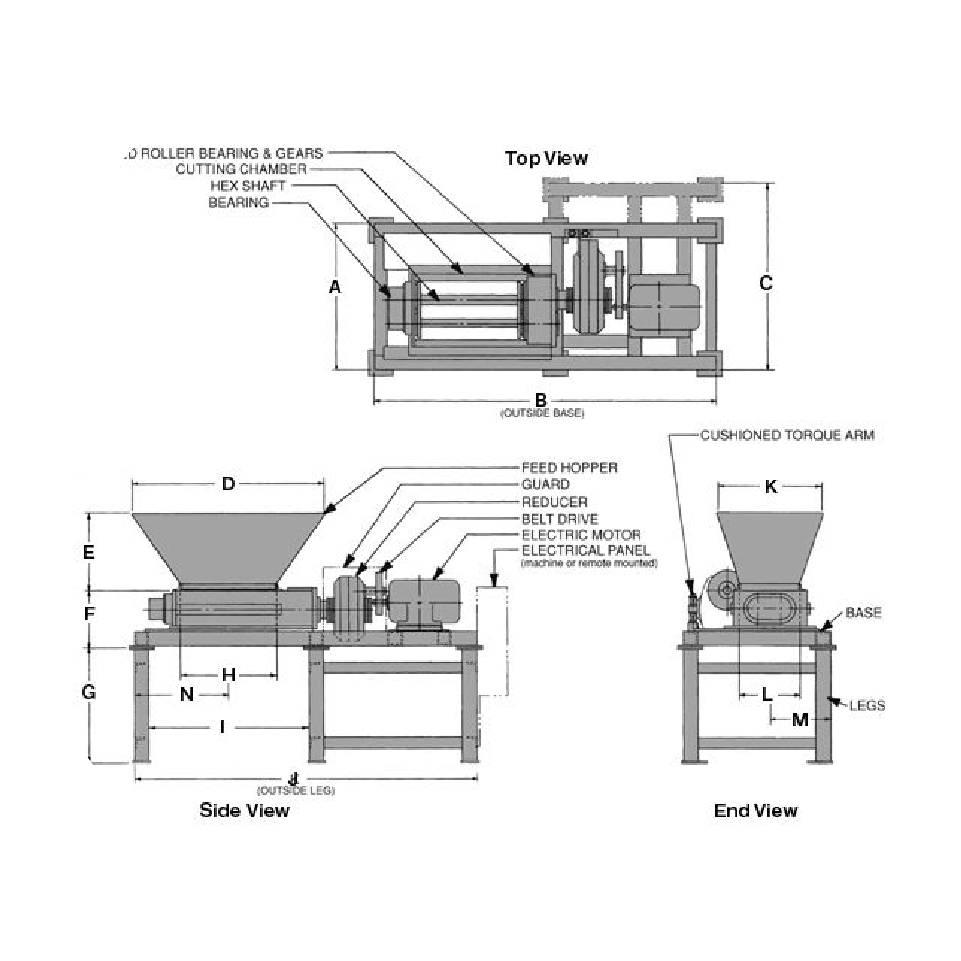

2. Plastic Recycling

Plastic waste collected is processed ready for use as a feedstock to make new things from.

This involves sorting the plastic types, cleaning the plastic, and then shredding the plastic into granulate pieces.

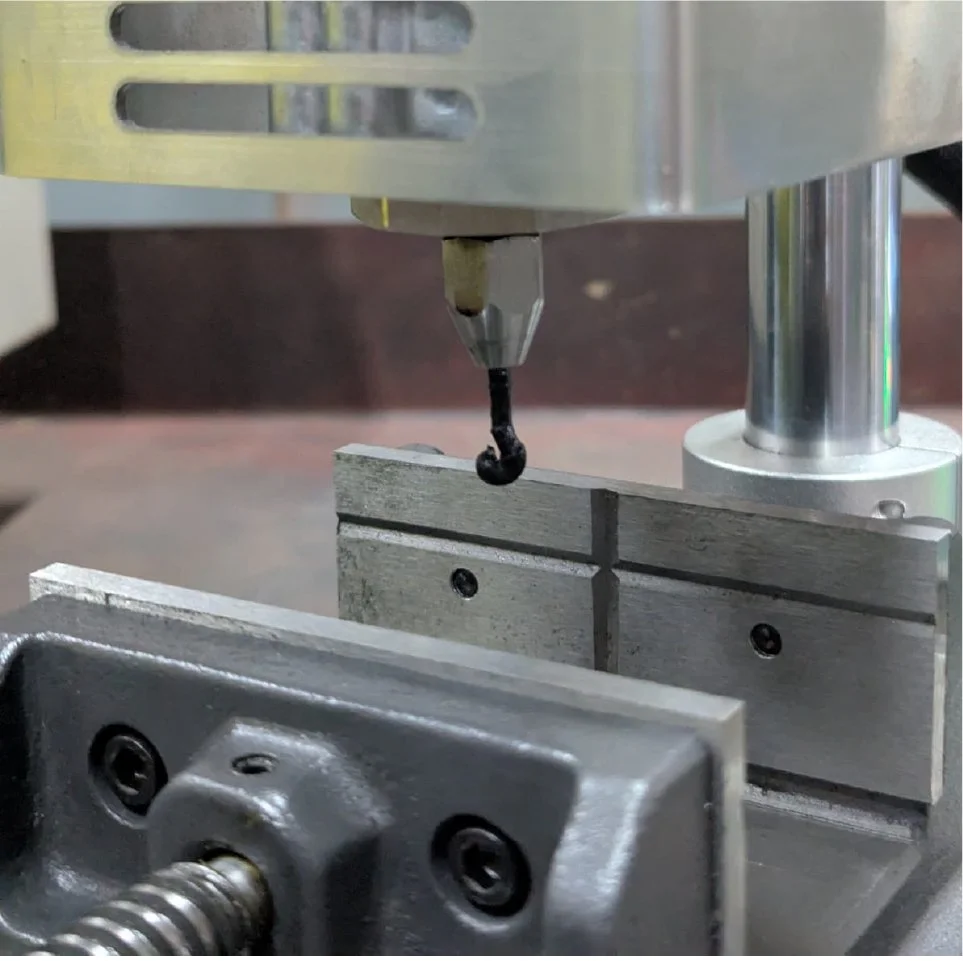

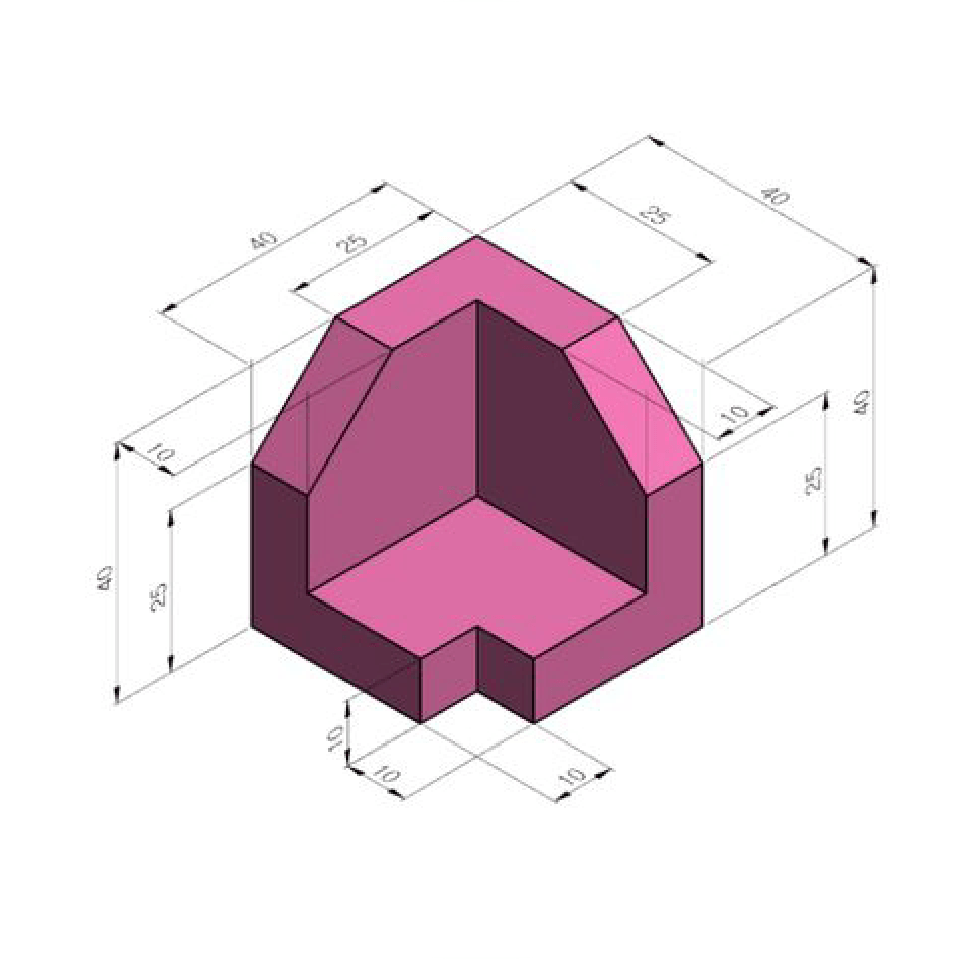

3. Circular Design & Production

With a circular design thinking approach, new

products/things are reviewed in-house at the workshop. Once approved, CAD designs are made for production moulds to be created.

The final steps are making the designs in small batches in-house with either craft-level extrusion or injection press machines.

Collaboration

Call-out

We are on the look-out for project volunteers and industry partners to help grow and develop the

remaking hub.

Currently we are looking for these contributors:

CAD designers

We are looking for people who can bring designs to life and spec to be made from moulds.

Mould makers

We are looking for mould makers who are interested in supporting circular economy community design projects.

Machinists

We are looking for mechanically able people to help revived some small machines in need of some love♡.

Upcoming events

Project Sponsors

Re Place

Acknowledgment of Country

We respect and honour Aboriginal and Torres Strait Islander

Elders past, present and future.

We acknowledge the stories, traditions and living cultures of

Aboriginal and Torres Strait Islander peoples on this land

and commit to building a brighter future together.